As wind turbine tip speed increases because OEMs chase more efficient machines with bigger rotors along with more exposure to rain, hail, sand, UV light, etc., the more wear and tear turbine blades must endure.

Polytech has analyzed data from 7,298 onshore sites (ex. China), which relate to 84,000 wind turbines and 252,000 blades) (data source Windpower.net). All analyzed turbines were commissioned between 2006 and 2017, with a minimum blade length of 40 meters.

Following the guidelines outlined in the DNV-RP-0573 (the recommended practice to evaluate and predict the durability of erosion protection systems), the analysis showed that eight of ten sites would have at least three meters of each blade damaged during its lifetime leading to loss of production and high repair costs. Today, however, many OEMs offer LEP only as an option for their turbine blades and use paint or coat as standard.

Our erosion calculations clearly show that many wind turbines are exposed to leading edge erosion. If left unprotected, they could experience blade damage in a very short time. Our test and validations have also shown that with the right solution you can protect the blades for more than 10 years before you have to protect again

From the data, it is impossible to identify blades with extra LEP solution.

However:

- 5,749 sites (equivalent to 66,015 turbines) require at least 3 meters of LEP. This means almost eight out of every ten turbines are susceptible to substantial wear.

- In the US alone, 27,242 out of 34,795 turbines (78%) are exposed to severe leading edge erosion.

- Alarmingly, for 19,163 turbines across 1,467 sites, a minimum of 20% of the blade length requires protection.

- For 596 sites (3,851 turbines), over 30% of the blades’ leading edge length would require repair or protection during expected lifetime of 25 years.

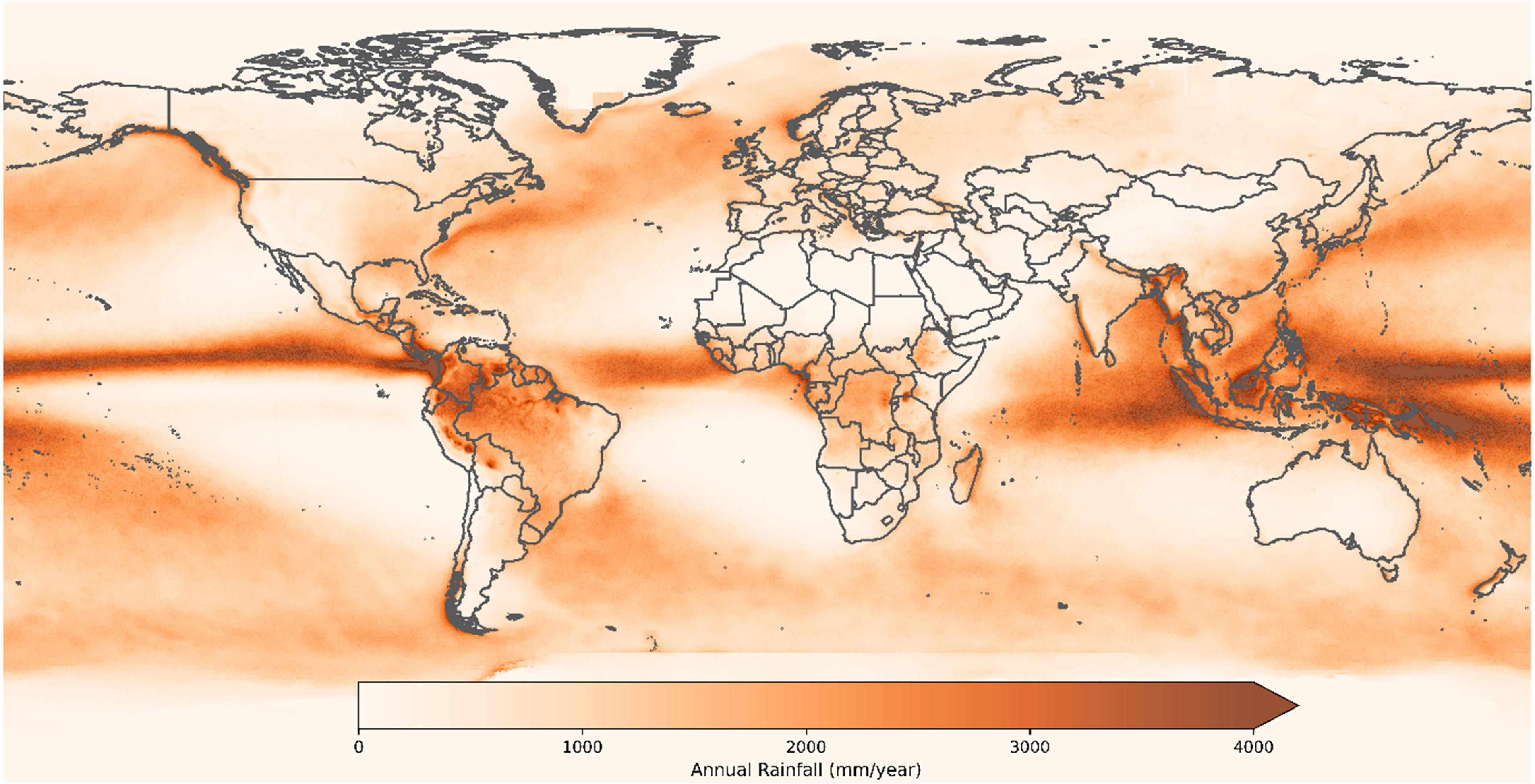

The most extreme sites prone to blade wear and requiring significant LEP are predominantly located in either rainy, snowy, or sandy locations:

- Norway

- United Kingdom

- Australia

- Thailand

- Canada

- USA

- Turkey

- France

Are any wind turbine manufacturers better or worse off than the others? Not really.

Vestas, SGRE, Enercon, GE, and Nordex, all have turbines operating at high tip speeds and/or are located in areas with particularly harsh environmental conditions.

Wind turbines located in heavy rainfall areas are most exposed to leading edge erosion.

Conclusion

While our previous discussions on this blog have highlighted the significance of LEP and the balance between protection and performance, this data-driven analysis further underscores the importance of leading edge protection solutions.

As the wind energy sector expands, manufacturers and operators must prioritize blade protection to maximize AEP, reduce maintenance costs, and extend turbine lifespan. Leading edge protection is not just a recommended practice; it's becoming an industry imperative. To all.

Read our other blog posts about which LEP solution is the right for you or find our solutions here.