Børsen Sustainable Cases (in Danish, Børsen Bæredygtig Cases) brings together green projects from medium to large-sized companies in Denmark that are developing innovative solutions to advance the green transition.

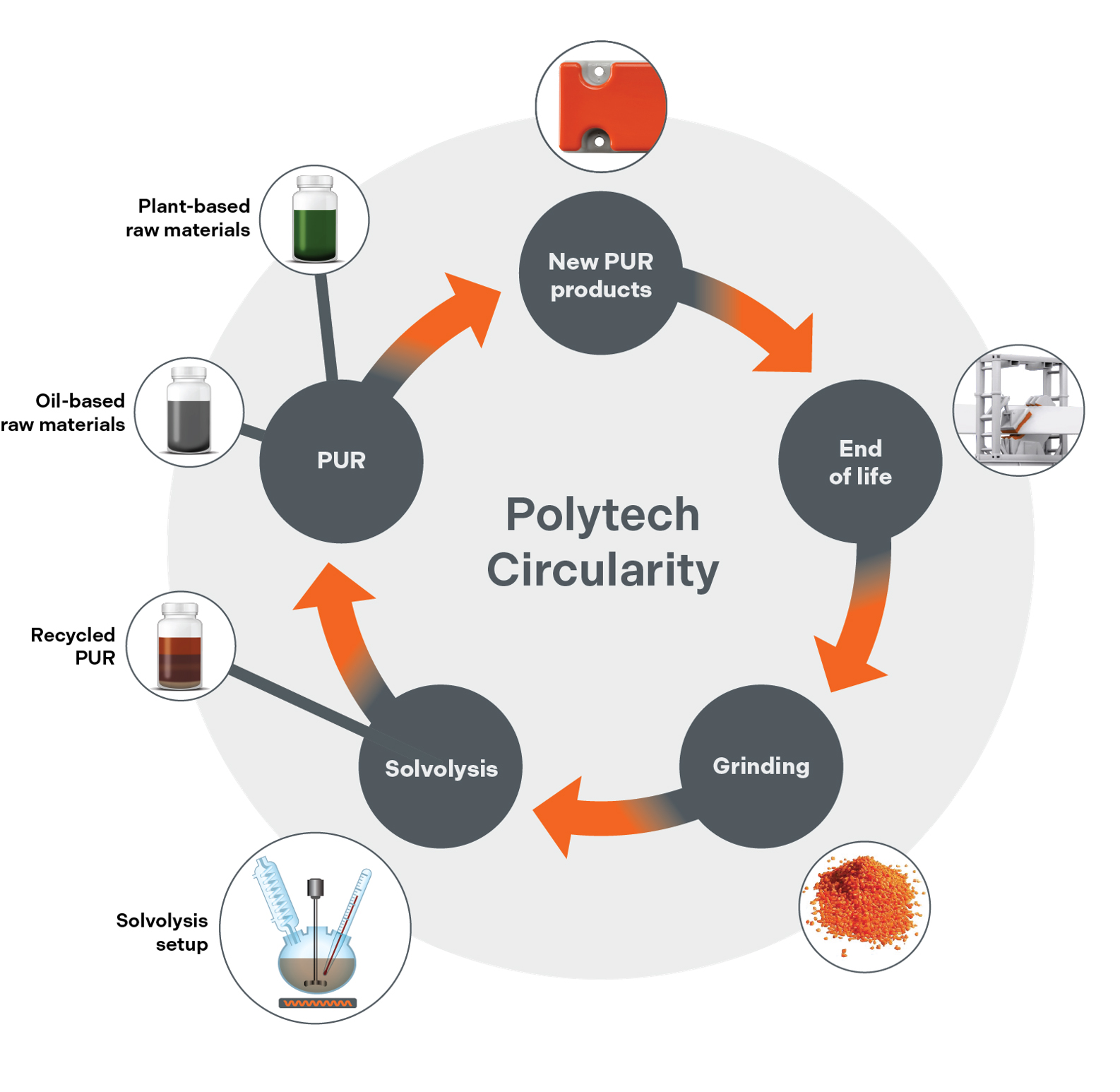

We submitted the project 'Circular approach to wind turbine transportation through recycling of polyurethane interfaces'. The project describes how we are reducing the CO2 footprint of our polyurethane (PUR) interfaces that are used on transport equipment to protect the wind turbine components, such as blades and towers, during transport.

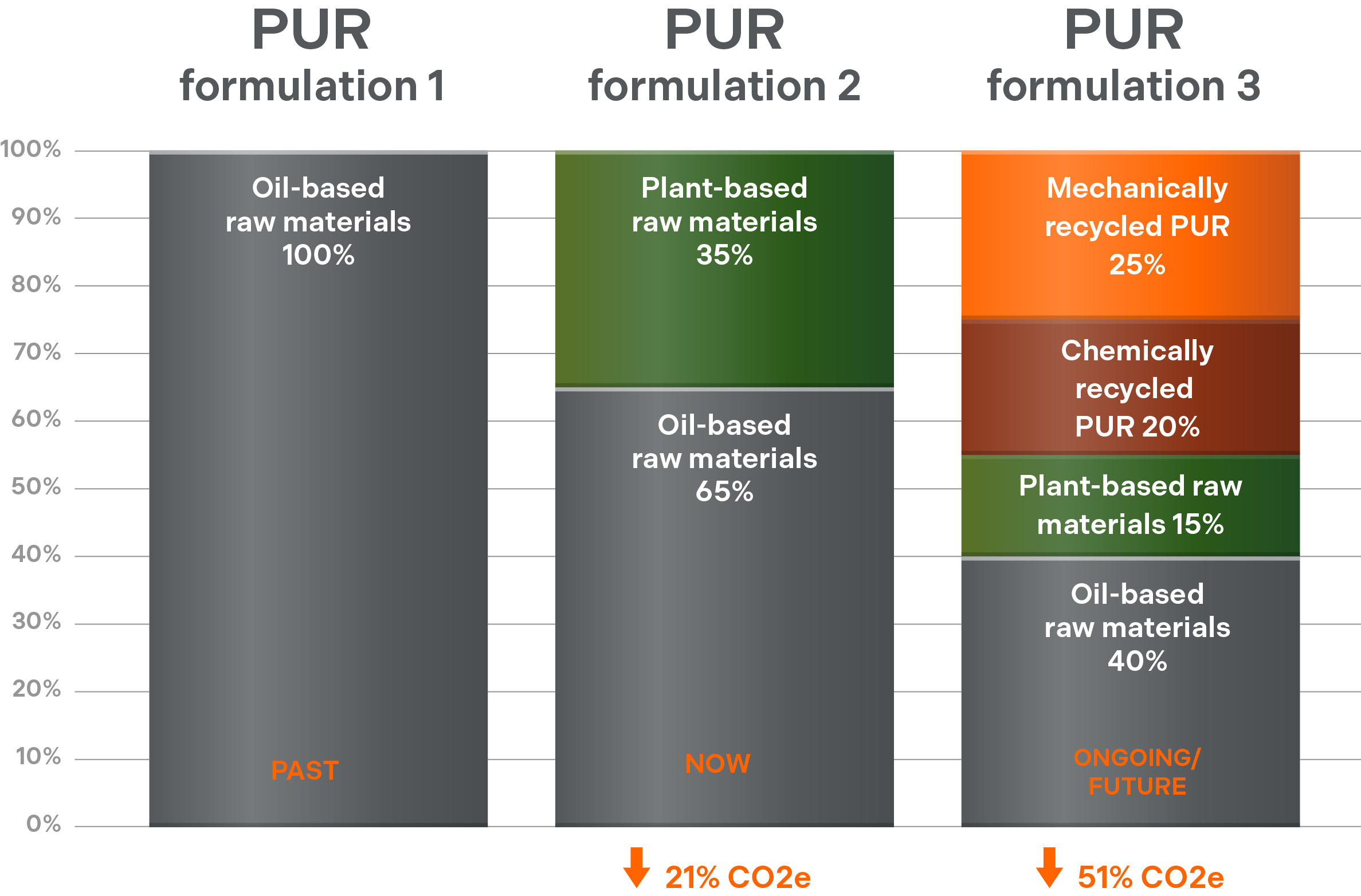

By replacing some of the oil-based raw materials in the PUR with plant-based raw materials, we have reduced the CO2 footprint of our PUR transport interfaces by 21%. We, however, have also proved that we can reduce the CO2 footprint of the interfaces by 51% in the future.

Green projects from all over Denmark were submitted to Børsen for review. Børsen’s expert advisory board chose the 50 most distinguished and innovative cases – one of them being Polytech’s project.

Polytech’s CEO Mads Kirkegaard welcomes this recognition by Børsen.

We are extremely proud of what we have achieved with the PUR recycling and reformulation, and that Børsen recognizes the significance of our project. Every year, the industry emits around 21,000 tons CO2e when producing new PUR interfaces for wind turbine transport equipment. This is an emission that we can now significantly reduce through recycling of PUR interfaces.

At Polytech, sustainability forms an integral part of the our operations, product portfolio, and business models. Certified by Bureau Veritas in the UN’s 17 Sustainable Development Goals in 2020, we continue our journey on being the frontrunner of sustainable wind.

"For us it is essential that what is good for business is also good for the environment. We are not just developing solutions that improve the durability and performance of wind turbines. We are pushing boundaries and questioning the status quo by introducing sustainable materials, circular business models, and proving how a more durable solution is better for our customers’ business in the long term – and of course for the environment. Today, we still see that product cost wins over total lifetime cost, which means that cheaper and less durable materials are preferred over more durable solutions. And this has a major impact on our environment. We always advise our strategic partners to consider total lifetime costs; it is better both for their business and the environment", adds Mads Kirkegaard.

Read Polytech’s submitted case ‘Circular approach to wind turbine transportation through recycling of polyurethane interfaces’ on Børsen's Sustainable Cases website.