Recent laboratory tests have again confirmed: our polyurethane softshell, ELLE®, in fact puts an end to leading edge erosion. We have followed the DNV-RP-0573 to evaluate and predict the durability and risk of delamination of our leading edge protection, ELLE®. And the result? ELLE® remains intact and will show no erosion during the lifetime of the turbines at most sites in the world.

So if you want to avoid unnecessary services, lower your maintenance cost, and optimize your operating expenses, then ELLE® might be the right solution for you.

Methodology - from testing to lifetime estimation

The DNV-RP-0573 provides a methodology to evaluate and predict the durability of erosion protection systems. We have followed this recommended practice to forecast the durability of ELLE®.

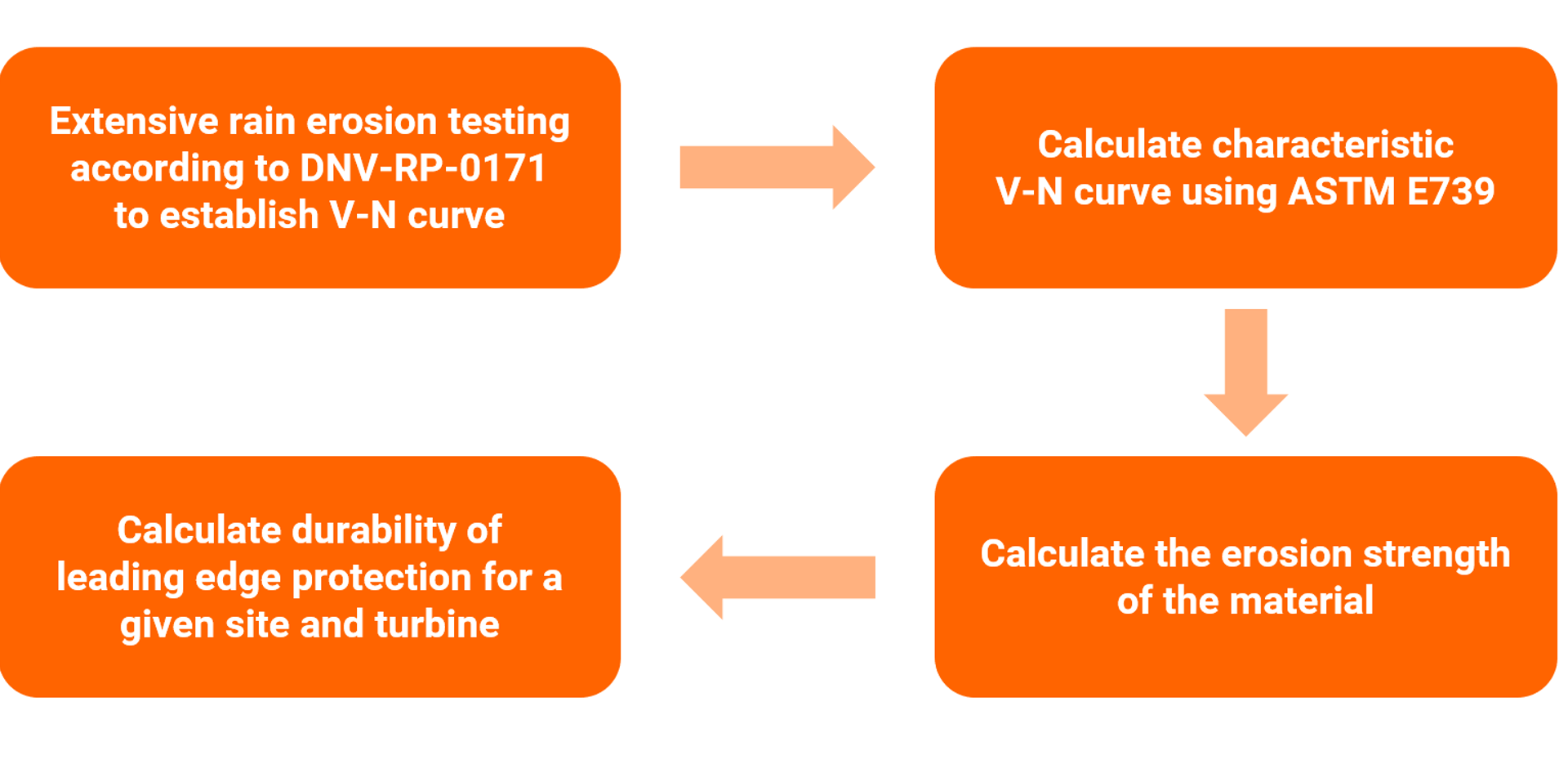

The process involved:

- Extensive rain erosion testing of ELLE® according to DNV-RP-0171

- Statistical analysis of data as per ASTM E739 standard practice

- Combining the rain erosion testing and statistical analysis with material properties such as density, speed of sound and thickness allows us to calculate the erosion strength of ELLE®

- Utilizing site- and turbine-specific data, such as annual rainfall, average wind speed, tip speed ratio, tip speed and blade length, we can calculate the durability of ELLE® for any given site

The process to calculate LEP durability based on DNV-RP-0573

Results - proven lifetime durability for ELLE®

We have calculated ELLE®’s durability for various sites and turbines around the world. The results show that:

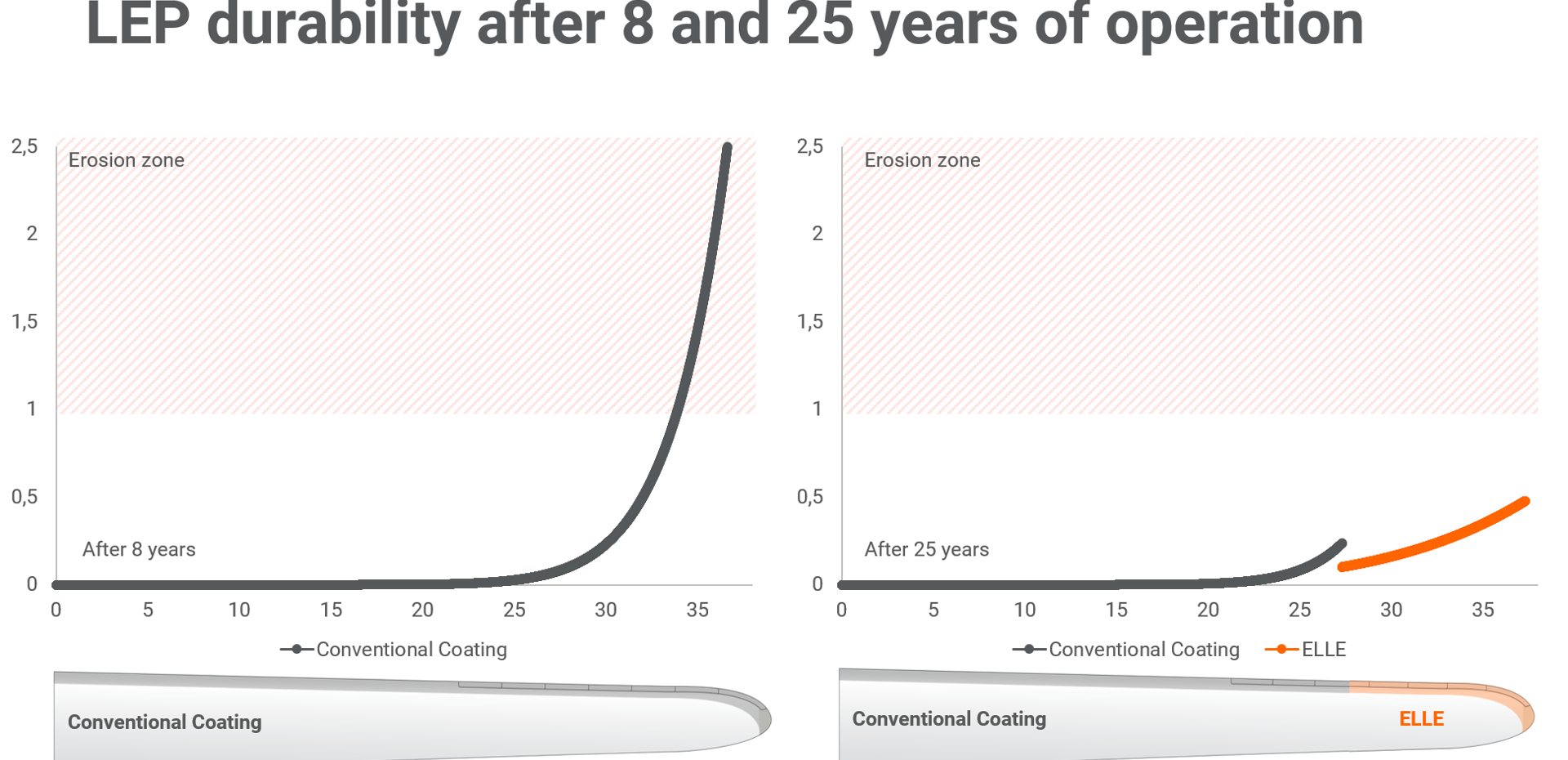

- In the vast majority of cases, ELLE® remains in the incubation period for 25 years of operation (i.e., it will not enter the erosion period, nor will it suffer from breakthrough, and no repair is needed).

- For the most extreme sites with regards to tip speeds and rainfall, ELLE® may show erosion damage that would require repairs of the tip sections maximum twice during the turbine's lifetime. These repairs, however, would only entail exchanging the damaged shell(s).

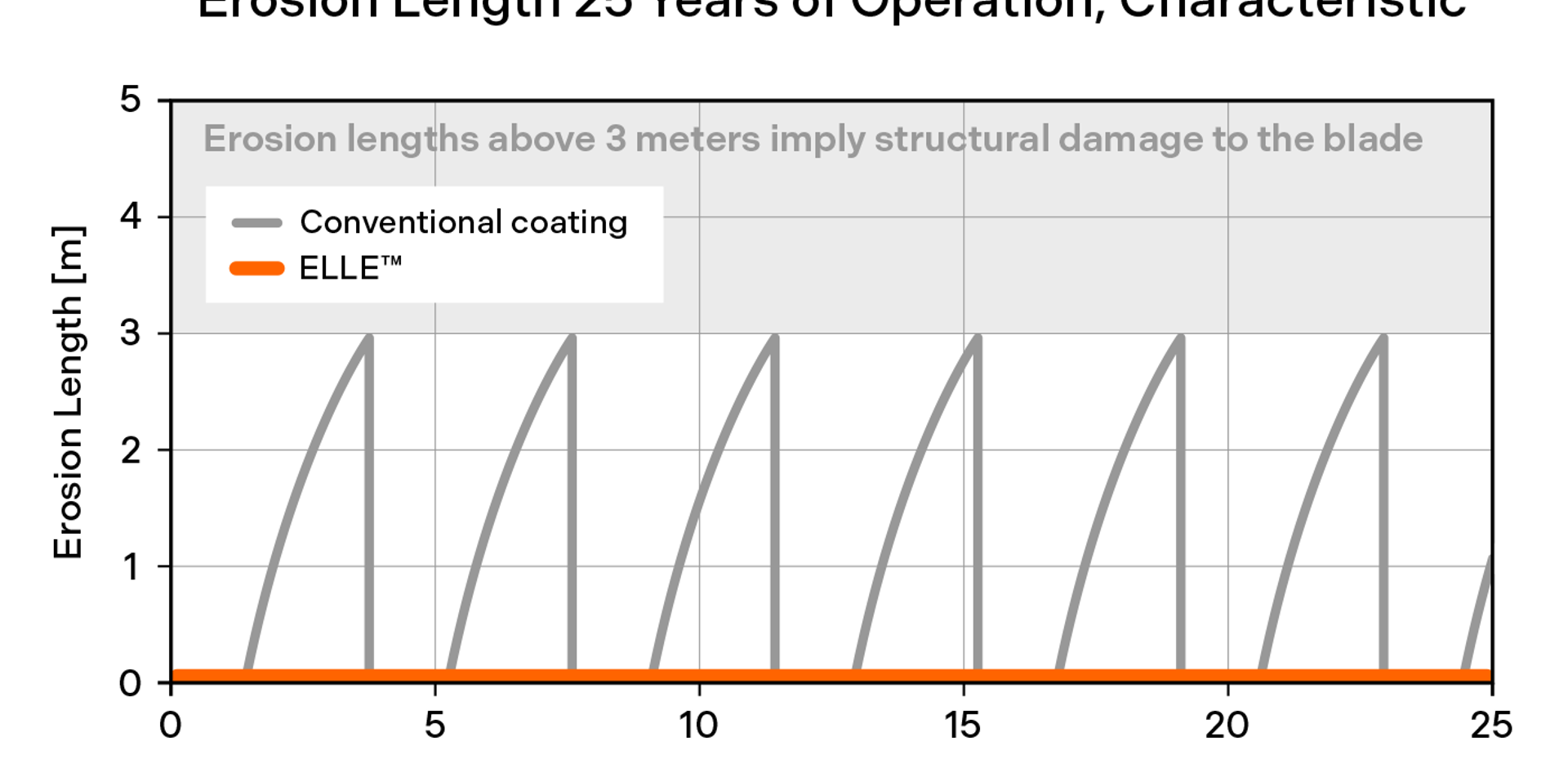

- When using only conventional coatings at sites sites with around 1,000mm annual rainfall, the leading edges will have visible erosion damages after a few years, which will require repairs up to six times over 25 years. For more extreme sites, this number can be even higher.

- Conventional coatings will experience severe erosion in the tip section and along the entire blade, which will require repairs. Installing ELLE®, however, will not only protect the tip of the blade, but also the rest of the leading edges from experiencing severe erosion during 25 years of operation

ELLE® prevents several repairs over 25 years

Example field case showing that ELLE® prevents 6 repairs over 25 years. (Input parameters: turbine type: 1.5 MW, rotor diameter: 77 m, blade length: 37.3 m, nominal RPM: 18.36, annual rainfall: 1,600 mm, mean wind speed: 8.5 m/s)

ELLE® installed on tip protects the entire blade against erosion during the 25 years of operation

Example field case showing the accumulated erosion damage on a blade after 8 and 25 years of operation with and without ELLE®. ELLE® protects the blade from erosion throughout the turbine’s lifetime. (Input parameters: turbine type: 1.5 MW, rotor diameter: 77 m, blade length: 37.3 m, nominal RPM: 18.36, annual rainfall: 1,600 mm, mean wind speed: 8.5 m/s)

But how durable would ELLE® be at your site? How many meters of your blades should be protected? And what the erosion risks at your turbine site?

Use our leading edge erosion calculator to find out!