Polytech

Leading edge protection with Polytech

Enhance your blade performance, reduce your operating costs, and improve the levelized cost of energy (LCoE). Top that with a solution designed to protect for a lifetime, and you get ELLE®- Everlasting Leading Edge. For any site. Offshore. Onshore.

Fast (and easy) leading edge protection of your blades

10 meters/32 feet of top of the line Leading Edge Protection installed in less than 60 minutes. Experience the speed and efficiency of ELLE® Onshore — our advanced leading edge protection solution. Preparing the surface and installing 10 meters to protect a blade takes less than one hour (58 minutes to be accurate in this video), allowing you to quickly return to full operation after one hour of curing time.

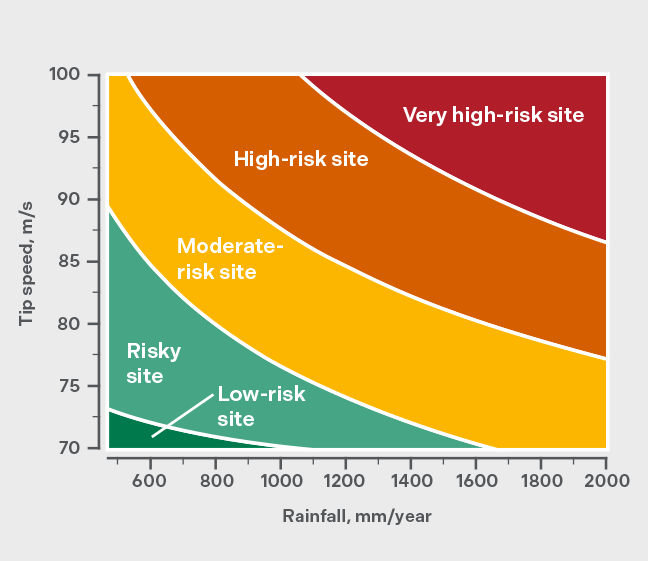

Site-specific leading edge protection

Your turbines will experience significantly different leading edge erosion rates depending on their location and types. This makes it difficult to choose the right leading edge protection – and complicated to forecast its durability and financial value.

But once you know your erosion risks, you can decide on the most optimal LEP strategy.

At Polytech, we have developed site-optimized leading edge protection solutions to make your choice easier:

- ELLE® Onshore for onshore environments and moderate-risk sites

- ELLE® for offshore environments and high to very-high risk sites

Leading edge erosion calculator

Our leading edge erosion calculator follows the DNV-RP-0573 and evaluates and predicts the durability of erosion protection systems. This way, we can calculate leading edge erosion at your specific site for your specific turbine.

You will also get to see how our ELLE® solutions would protect your turbines at the site.

Meet the ELLE® family

Site-optimized Leading Edge Protection. Anyplace. Anywhere. Anytime

| Installation during manufacturing | ||

| Retrofit | ||

| Application conditions –temperature (°C) | 10-35°C | 5-35°C |

| Application conditions – relative humidity (RH) | 0-100% RH | 30-90% RH |

| Sealer | - | |

| Pressure-sensitive adhesive | ||

| Aerodynamic performance achieved by... | Chamfered edges & wide design | Blade-customized design, chamfered edges & sealer chamfering |

| Fit | Standard that fits most blades | Custom to fit specific blade design |

| Delivery | On continuous, 33m-long rolls (cut and install) | 1 m pieces in sealed vacuum bags |

| Shelf life | Up to 18 months | Up to 18 months |

| Training | - |

The most durable material on the market

We know materials. We are born out of polyurethane (PUR); one of the strongest, most versatile, and most durable industry materials, hence our name Polytech.

25+ years of material R&D, accredited laboratory testing, field exposure tests, and field validation on more than 70,000 blades.

All this is behind the chosen material for ELLE®.

The ELLE® surfaces are designed and dimensioned to absorb the kinetic energy from all airborne particles, including rain, hail, and sand.

As such, ELLE® perfectly protects the rigid fiberglass surface of the blade.

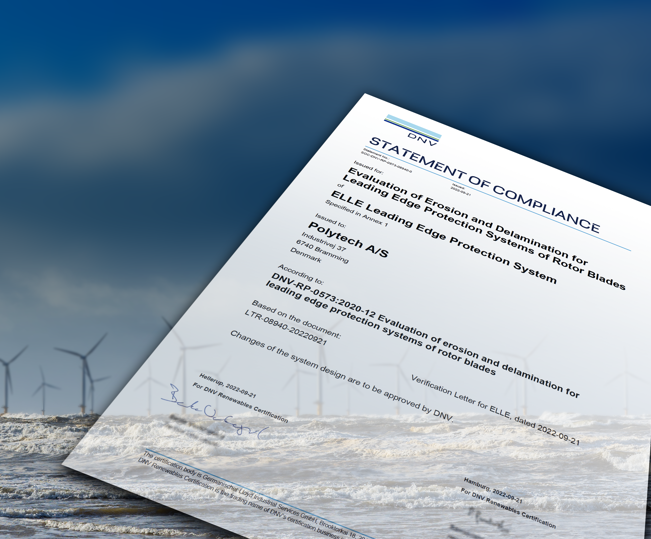

DNV verified ELLE®'s

- erosion strength,

- risk of delamination,

- test results, and

- lifetime durability calculations

according to DNV-RP-0573.

As such, ELLE® is currently the only leading edge protection solution on the market that is verified by DNV. You can therefore trust its durability – and the expertise that lies behind our ELLE® solutions.

ELLE® can be applied during manufacturing but can also be retrofitted to your installed base.

Require your OEM to install ELLE® during blade manufacturing for your turbines. Installation in this controlled environment eliminates any dust, air bubbles, etc. under ELLE®, and can lower common installation mistakes.

And if you have operating turbines, then it is not too late. You can easily apply ELLE® using rope or basket. We know that installations might be postponed at the very last minute due to, e.g., bad weather. That is why we designed our solutions with a wide application window.

Preview how easy and quick ELLE® Onshore can be installed right here: Install Polytech's ELLE® Onshore: 58-Minute Blade Setup

Contact us

Get in touch with our Sales team directly or contact our Business Development Director Claus Holk Poulsen (for OEM customers) or Head of Aftermarket Marc Foldager (for aftermarket customers) to learn more about how our solutions can optimize your operations.

From the Field: Stories & Updates on ELLE® Protection

Get inspired by the latest stories, technical articles, and field success reports around ELLE® Leading Edge Protection. Learn how our solutions are tested, proven, and continuously improved to meet the toughest challenges in wind energy. Dive into our news and see innovation in action.