Polytech

Mechanical Testing: Book Your Session Now

Ready to get started?

Choose a convenient time to visit our test and validation center in Bramming.Our expert team is here to assist you every step of the way. Whether you have specific tests in mind or need guidance, we’re ready to help.

Who Benefits from Our Testing Facilities?

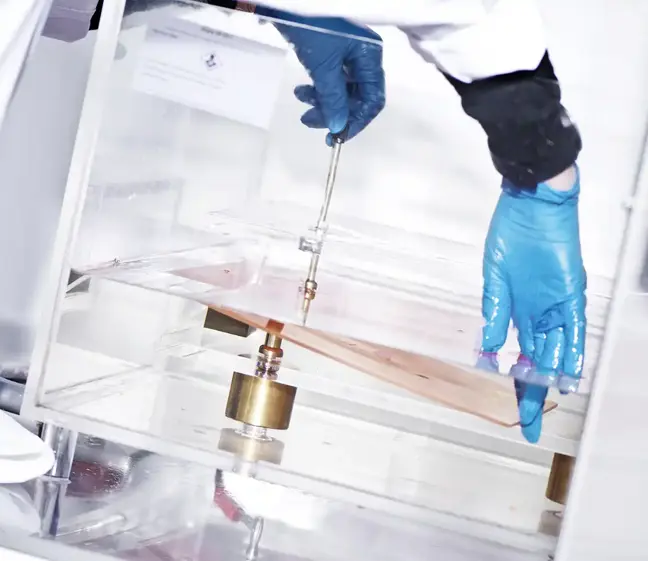

At Polytech, we understand that early mechanical and weathering testing is crucial in identifying potential design weaknesses before full-scale production. Our Mechanical Test Center in Denmark offers flexible and cost-effective testing services to support your development process, whether you're testing structural components, mechanical systems, or custom prototypes.

Our state-of-the-art test centers perform both standardized and validated, non-standardized tests that are customized to meet the needs and requirements of each individual customer. With advanced equipment and a highly experienced team, we ensure reliable results tailored to your specific product and test scenario.

Explore our standard pricing below, and reach out for a tailored proposal based on your requirements.

| Example of services | Prices starting from |

|---|---|

|

€670 |

|

€1200 |

Weathering tests

Our material laboratories perform accelerated weathering tests, simulating a lifetime of wear and tear from UV, salt, and extreme climate exposure. This rigorous process provides validated data on long-term durability, crucial for predicting performance in harsh operational environments. We can simulate years of exposure in weeks or months depending on the climate and material you want to test.

|

Rain Erosion |

DNV-RP-0171 |

Recommended practice to test liquid impingement erosion using rotating apparatus |

|

Xenon-arc Lamps |

ISO 16474 |

Paint and varnishes – Methods of exposure to laboratory light sources |

|

ISO 4892-2 |

Plastics – Methods of exposure to laboratory light sources. Part 2: Xenon-arc lamps |

|

|

ASTM G155 – 13 |

Standard practice for operating Xenon Arc light apparatus for exposure of non-metallic materials |

|

|

Fluorescent UV |

ISO 4892-3 |

Plastics – Methods of exposure to laboratory light sources – part 3 Fluorescent UV lamps |

|

ISO 16474-3 |

Paints and varnishes - Methods of exposure to laboratory light sources. Part 3: Fluorescent UV lamps |

|

|

Gloss |

ISO 2813 |

Paint and varnishes – Determination of gloss value at 20°, 60° and 85° |

|

Offshore |

ISO 12944-9 |

Paint and varnishes – Performance requirements for protective paint systems for offshore and related structures. |

|

Salt Spray |

ISO 9227 |

Corrosion tests in artificial atmospheres – Salt spray tests |

Tensile tests

|

Tensile - General |

ISO 527 part 1, 2 and 3 |

Plastics – Determination of tensile properties Part 1: General principles Part 2: Test conditions for moulding and extrusion plastics Part 3: Test conditions for films and sheets |

|

|

ISO 37 |

Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties |

|

Peel |

ASTM D 3330 |

Standard test method for peel adhesion of pressure-sensitive tape |

|

ISO 4578 |

Adhesives – Determination of peel resistance of high-strength adhesive bonds – Floating-roller method |

|

|

Shear |

ISO 4587 |

Adhesives — Determination of tensile lap-shear strength of rigid-to-rigid bonded assemblies |

|

Tear |

ASTM D-624 |

Standard test method for tear strength of conventional vulcanized rubber and thermoplastic elastomer |

|

ISO 34 |

Rubber, vulcanized or thermoplastic – determination of tear strength |

Compression tests

|

ISO 844 |

Rigid cellular plastics — Determination of compression properties |

|

ISO 604 |

Determination of compressive properties |

|

ISO 7743 |

Rubber, vulcanized or thermoplastic — Determination of compression stress-strain properties |

|

ISO 815 |

Rubber, vulcanized or thermoplastic — Determination of compression set |

Other tests

|

DSC (-90°C to 300°C) |

ISO 11357 part 1, 2 and 3 |

Plastics - Differential scanning calorimetry (DSC) Part 1: General principles Part 2: Determination of glass transition temperature and glass transition step height Part 3: Determination of temperature and enthalpy of melting and crystallization |

|

Density |

ISO 1183 |

Plastics - Methods for determining the density of non-cellular plastics Part 1: Immersion method, liquid pyknometer method and titration method |

|

Water Absorption |

ISO 62 |

Plastics - Determination of water absorption |

|

Shore Hardness |

ISO 868 |

Plastics and ebonite - Determination of indentation hardness by means of a durometer (Shore hardness) |

|

Climate Cycling |

Customer specific |

|

|

Customized Tests |

Customer specific |

|

Book your timeslot for mechanical testing today

Still in doubt?

Get in touch with our Test & Validation team directly or contact our Manager of Test & Validation in Bramming Andreas H. Bjerrum to learn more about your possibilities with our services with testing and validation.